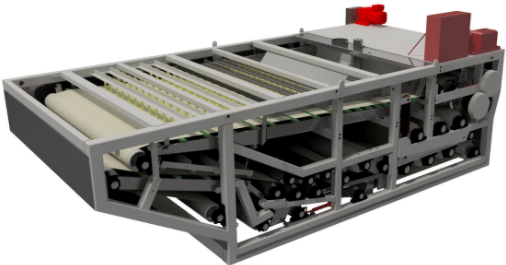

SALTEC HP

Saltec HP usually used in paper mills, chemical and mining industries.

Information

Higher dry solids content can now be achieved thanks to the optimized roller configuration. The single roller gradations have been completely revised and the pressing time within the machine considerably extended. This is particularly advantageous when dealing with sludges with low press stability and a high organic content. Minimum operating costs (flocculant, energy, water) and highest efficiency-class motors guarantee the lowest possible energy consumption figures. Cleaning and handling operations are now even easier thanks to the introduction of a larger inspection opening.

Capacity: 5-50 m3/h

TS-OUT: 20-60%

Saltec HP uses a unique process technology consisting of 6 dewatering phases, this Press achieve maximum yield and highest overall capacity compared to other Presses on the market. The slow and smooth build-up of pressure to the high pressure area leading to optimum results.